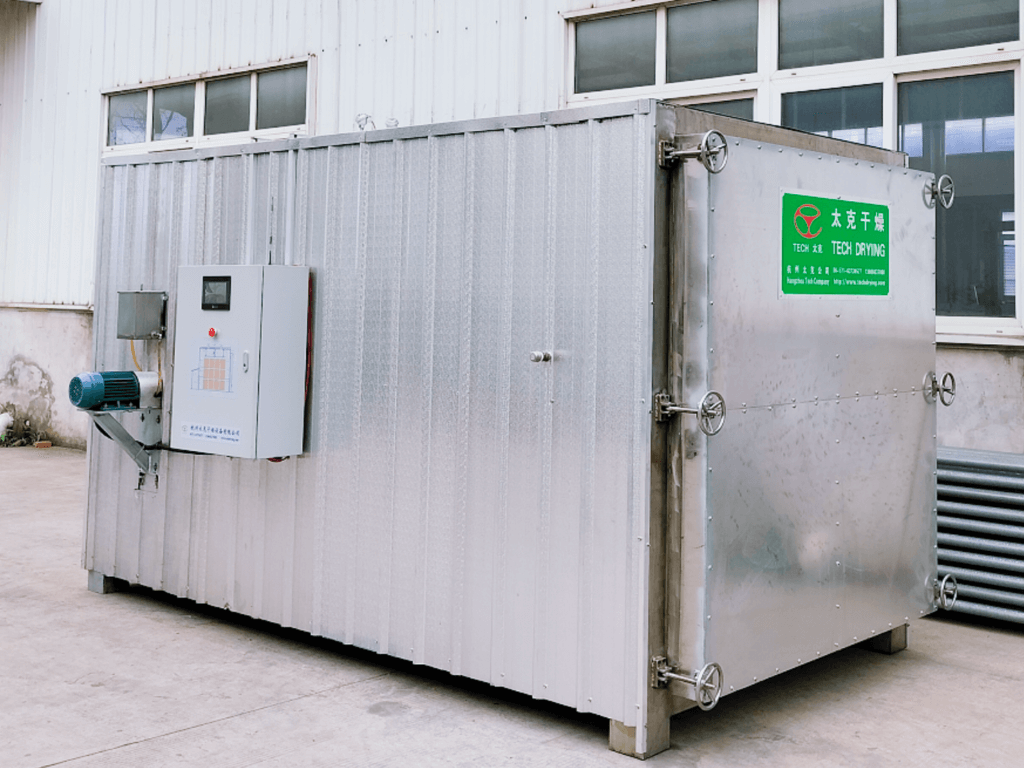

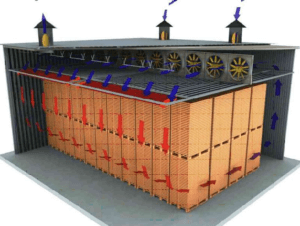

Heat Recovery Tech

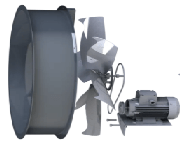

Through the ingenious application of engineering thermodynamics, the kiln is furnished with an advanced evaporative heat recovery function. This function can effectively capture the? the latent energy released from the moisture – laden wood,accelerating drying and achieving substantial energy savings.

?

?