PLC Automatic Control System

PLC Automatic Control System

Technical Parameters:

EMC Test Points: 2

Temperature Test Points: 2

Wood Moisture Content Test Points: 6 – 12

EMC Test Points: 2

Temperature Test Points: 2

Wood Moisture Content Test Points: 6 – 12

Features of TECH PLC Control System:

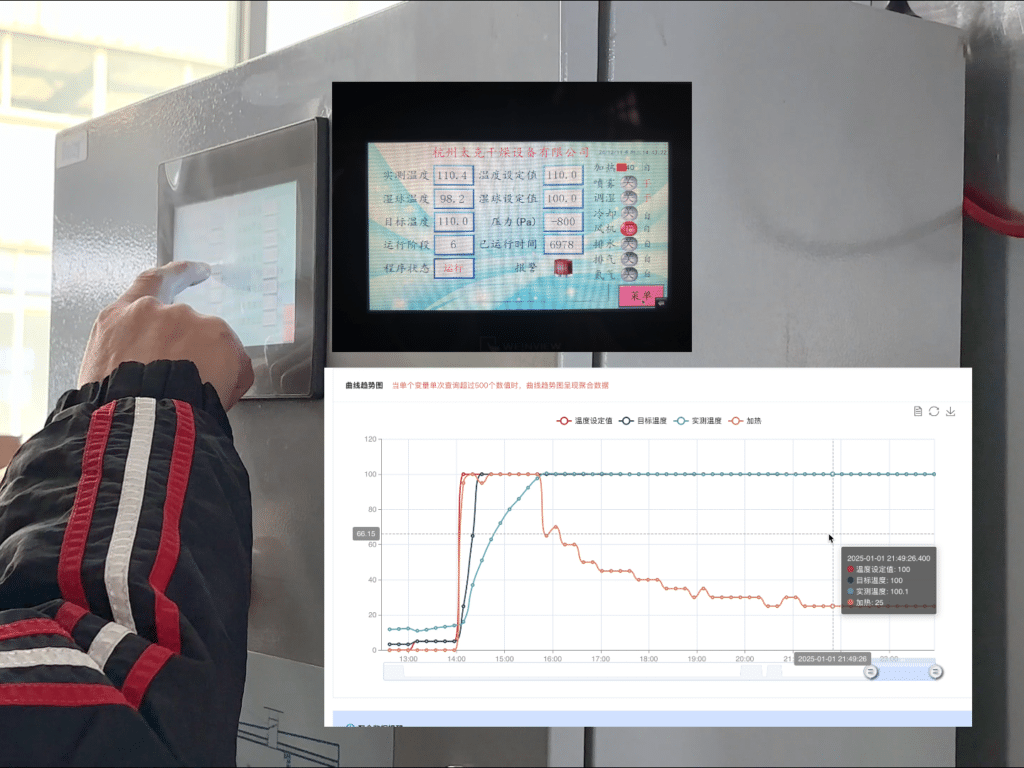

- User – friendly Operation Interface: The PLC control system is equipped with an intuitive graphical display screen, providing an easy – to – operate platform. Even non – professionals can easily set parameters. All configurations are completed through simple and clear menus, and advanced settings are protected by secure sub – menus, ensuring both the convenience and safety of operation.

- Remote Management via Cloud Platform: The PLC control system is connected to the cloud platform, supporting remote monitoring operations on both mobile phones and PCs. It enables remote control of the equipment, real – time viewing of temperature and humidity change curves, data management, and receiving of alarm notifications, among other functions.

- Flexible Drying Cycle Control: The PLC control system allows the drying cycle to be divided into up to 11 stages, and each stage can be customized to meet the drying requirements of different types of wood and fulfill the heat treatment requirements for packaging boxes.

- Pre – set Drying Programs: TECH can provide drying standard programs that cover a variety of wood types, which are especially suitable for beginners or users with regular drying needs.

- High – precision Measurement Technology: TECH PLC control system can precisely control temperature and humidity within ±0.5°C. By adopting a new type of probe amplifier, combined with AC variable voltage measurement and digital filtering technology, it ensures high measurement reliability and strong resistance to power supply interference. The probe amplifier is housed in a sealed aluminum shell, which has good dust – proof performance, and is equipped with a shielded cable insulated with Teflon? to guarantee the accuracy of measurement.

- Technology Integration: The system integrates the innovative “Smart Button” technology for storing and calling drying programs, effectively preventing unauthorized modifications and facilitating software upgrades at the same time. Users can start the drying cycle through simple touch operations, simplifying the operation process, and can also perform program transmission or updates.

- Compatibility and Expandability: Designed based on the PLC system, it is compatible with existing and future – developed sensors and actuators, providing unlimited possibilities for system upgrades. Meanwhile, the equipment supports both RS232 and RS485 dual – standard serial interfaces, making it convenient to connect with the main control computer.

- Modular Design: The structure of the PLC controller adopts a modular design, which is divided into a visualization module and a power supply module, making the installation more flexible and the wiring tidier. The two modules are connected by a pre – assembled cable, simplifying the installation and maintenance processes.

?

Related Products

Conventional Wood Drying Kiln

TECH Conventional Wood Drying Kiln (ZQ Series) is a versatile dryer. It can use steam, hot water, thermal oil, or electricity as the heating medium, operating at a drying temperature of 100℃ (212℉) or less. This makes it suitable for both softwood and hardwood, meeting various wood processing needs.

Our ZQ series kiln dryers, installed in 46 countries worldwide, are remarkable for their reliability and high efficiency. Our innovative technology precisely controls the drying process. This reduces lumber drying defects and ensures faster, more uniform drying, delivering high – quality results for our customers.