Hardwood High Temperature Kiln

Hardwood High Temperature Kiln

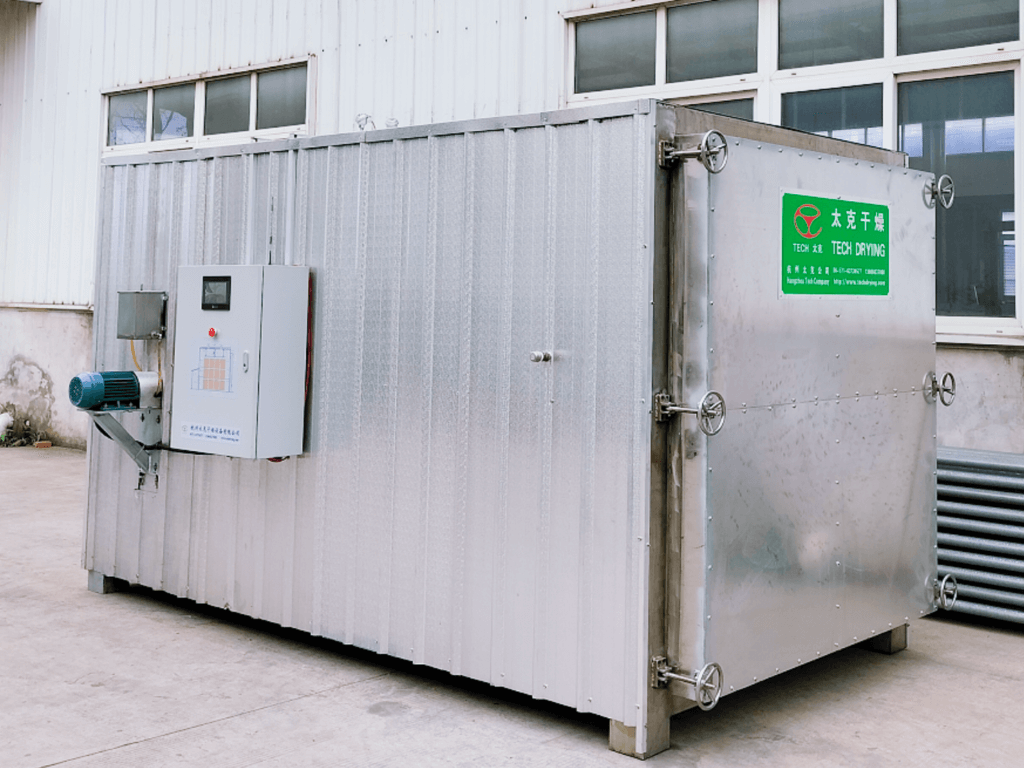

The TECH Hardwood High Temperature Kiln represents a state – of – the – art and high speed drying solution, meticulously designed for dense and thick hardwoods like rosewood. Its interior is crafted from American Standard 304 stainless steel, allowing the kiln to operate at drying temperatures that exceed 100°C (212°F), reaching up to 150°C (302°F).

By integrating advanced heat recovery and air circulation technologies, this kiln can achieve a drying speed 6 – 8 times faster than conventional kilns, all while maintaining top – notch wood drying quality.

Dense and Thick Hardwood

Heat Recovery & Thermal Break Tech

100-150°C (212-302℉) High-Temp Drying

6-8 Times Faster than Conventional Kiln

Unmatched Energy Efficiency

High Temperature Kiln Specification

| Specification | Details |

| Model | GWD/GWY/GWQ |

| Capacity | 2 – 20m3 (Customizable for other sizes) |

| Maximum Temperature inside the Kiln |

150 ℃ (302°F) |

| Applicable Lumber Types | Hardwoods such as Rosewood, etc. |

| Loading Method | Rail Car |

| Kiln Structure Material | 304 Stainless Steel Inner Wall |

| Heating Medium | Steam / Thermal Oil / Electricity |

| Site Requirements | Indoor / Under Shelters |

Key Features

Heat Recovery Tech

Through the ingenious application of engineering thermodynamics, the kiln is furnished with an advanced evaporative heat recovery function. This function can effectively capture the? the latent energy released from the moisture – laden wood,accelerating drying and achieving substantial energy savings.

?

?

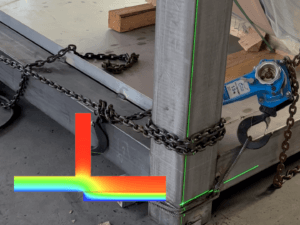

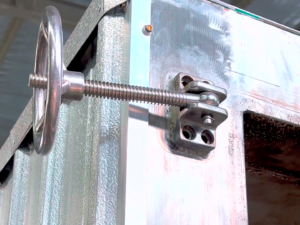

Thermal Break Design

Featuring 150mm thick insulation layer and thermal break design, minimizing thermal bridging, cut heat loss, retaining heat and maintaining a stable high temperature inside.

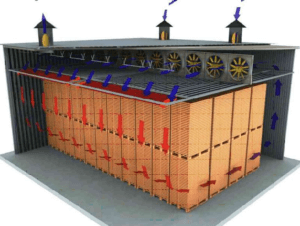

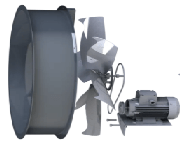

Air Circulation Tech

The unique design of the fan shaft structure and bearing lubrication enables the fans to be positioned anywhere within the kiln as required. This allows for precise regulation of the air dynamic circulation, ensuring a uniform heat flow distribution. Consequently, the drying uniformity and efficiency of the lumber are enhanced.

Durable Materials

The 304 stainless steel interior is corrosion resistant, ensuring long term stability and low maintenance.

曲02-e1740921820819-182x53.png)