What is Kiln Drying? The Science Behind Lumber & Timber Drying

From forests to furniture, from logs to refined flooring, every board hides a challenge: Moisture. And the silent hero behind every strong, stable, beautiful piece of wood? Kiln drying. It doesn’t make noise, but it makes all the difference — preventing cracks, warps, and wasted effort. If you turn wood into something that lasts, kiln […]

This post What is Kiln Drying? The Science Behind Lumber & Timber Drying first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

What is Kiln Drying? The Science Behind Lumber & Timber Drying

This post What is Kiln Drying? The Science Behind Lumber & Timber Drying first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

How kiln dryer Works: A Complete Guide for Kenya Buyers?

In the realm of woodworking, the role of the kiln dryers is indispensable. These advanced systems are engineered to reduce the moisture content of timber, making it suitable for a wide range of applications, from furniture production to wooden packaging materials. For Kenya buyers seeking efficient lumber drying kiln solutions, this comprehensive guide explores the […]

This post How kiln dryer Works: A Complete Guide for Kenya Buyers? first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

How kiln dryer Works: A Complete Guide for Kenya Buyers?

This post How kiln dryer Works: A Complete Guide for Kenya Buyers? first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Looking for a Wood Drying Kiln Near You? Here’s What to Consider

The wood drying kiln industry plays a vital role in the Kenya, contributing significantly in the drying kiln for lumber drying process. The ever-growing demand for high-quality and reliable wood processing solutions and lumber drying kilns necessitates understanding key factors when searching for a wood kiln close to home. Explore more at?Tech Drying. 1. The […]

This post Looking for a Wood Drying Kiln Near You? Here’s What to Consider first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Looking for a Wood Drying Kiln Near You? Here’s What to Consider

This post Looking for a Wood Drying Kiln Near You? Here’s What to Consider first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Solenoid Valve

Solenoid Valve Solenoid Valve for Spraying System Technical Parameters:Material: Stainless SteelDiameter: 20 – 100mmValve Opening and Closing Time: 30sFeatures: The spraying system of the drying kiln uses solenoid valves of a German brand. These solenoid valves feature reliable operation, corrosion resistance, and a long service life. The spraying system of the drying kiln is equipped […]

This post Solenoid Valve first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Solenoid Valve

This post Solenoid Valve first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Electric Valve

Electric Valve Electric Valve Caliber Range: DN20 – DN200Pressure Range: PN150 – PN420, ANSI 900 – ANSI2500Temperature Range: -29°C to +230°C, +230°C to +560°CLeakage Class: ANSI B16.104 IV, ANSI B16.104 VIMain Body Material: Stainless SteelDriving Device: Pneumatic, ElectricFeatures: The electric valve for the drying kiln heating system features reliable operation, corrosion resistance, and a long […]

This post Electric Valve first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Electric Valve

This post Electric Valve first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Heat Exchanger

Heat Exchanger Heat Exchanger Technical Parameters Base Tube: Crafted from top – tier Stainless Steel 304. This material is prized for its outstanding corrosion resistance, making it ideal for the demanding environment of a drying kiln. It can endure high humidity and temperature fluctuations over extended periods, ensuring long – term, trouble – free operation. […]

This post Heat Exchanger first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Heat Exchanger

This post Heat Exchanger first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Fan System

Fan System Fan System (Aluminum Alloy Fan, High – Temperature – Resistant Motor) The air circulation system hinges on a reversible fan system, strategically installed above the ceiling of each drying room. These fans are engineered to be the linchpin of achieving high – quality, uniform wood drying.? Unparalleled Performance Consistency Regardless of whether they […]

This post Fan System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Fan System

This post Fan System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Siemens Electric Damper Actuator

Siemens Electric Damper Actuator Siemens Electric Damper Actuator The dehumidification system of the TECH drying kiln adopts the Siemens electric damper actuator GEB341.1E, which can precisely control the damper and has the characteristics of small size, reliable performance, and long service life.Technical Parameters: Model: GEB341.1E Torque: 20 Nm Dimensions (Width × Height × Depth): 81 […]

This post Siemens Electric Damper Actuator first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Siemens Electric Damper Actuator

This post Siemens Electric Damper Actuator first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

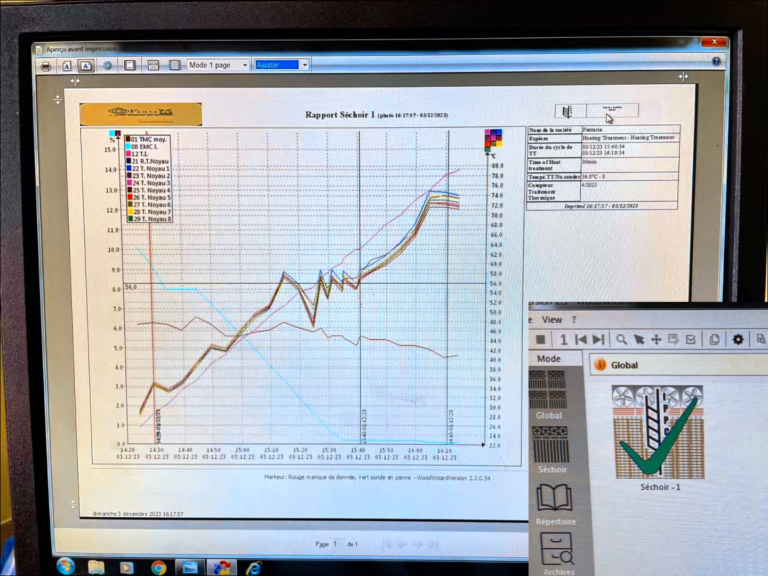

Hozmeister Automatic Control System

Italian Automatic Control System LiTOUCH Italian Automatic Control System HOZMEISTER M800B (Delphi) Technical Parameters: Brand: LOGICA Models: HOZMEISTER M800, M800B (Delphi),? Origin: Italy EMC Test Points: 2 Temperature Test Points: 2 Wood Moisture Content Test Points: 6 – 12 Features of HOZMEISTER M800B (Delphi): The fully automatic control system adopts a series of products from […]

This post Hozmeister Automatic Control System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Hozmeister Automatic Control System

This post Hozmeister Automatic Control System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

LiTOUCH Automatic Control System

Italian Automatic Control System LiTOUCH Italian Automatic Control System LiTOUCH Technical Parameters: Brand: LOGICA Origin: Italy EMC Test Points: 2 Temperature Test Points: 2 Wood Moisture Content Test Points: 6 – 12 Features of LiTOUCH: LiTOUCH is a natural evolution of the DELPHI control system, born from the combination of the advanced dTOUCH system and […]

This post LiTOUCH Automatic Control System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

LiTOUCH Automatic Control System

This post LiTOUCH Automatic Control System first appeared on TECH Drying Kiln and is written by shujin9213@gmail.com

]]>

Minimized Defects: By carefully controlling temperature, humidity, and airflow, kiln drying greatly reduces risks of warping, cracking, end checks, and case hardening.

Minimized Defects: By carefully controlling temperature, humidity, and airflow, kiln drying greatly reduces risks of warping, cracking, end checks, and case hardening.