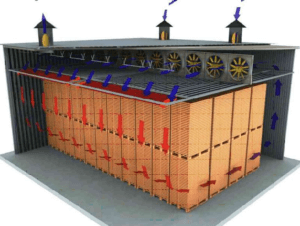

Robust Construction

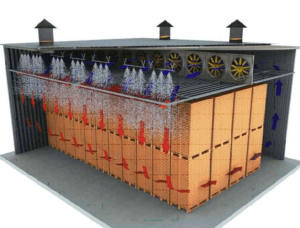

Kiln chamber walls constructed with rust-proof 3003 aluminum; main structure built with 6063 aluminum. Heat exchanger pipes and all connecting parts feature 304 stainless steel, ensuring leak-free operation. Modular design enables easy maintenance. Ferrous-free structure guarantees 20+ years of corrosion resistance and stability.

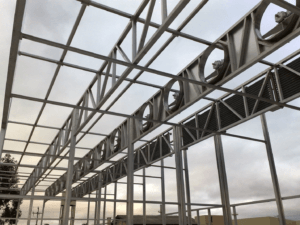

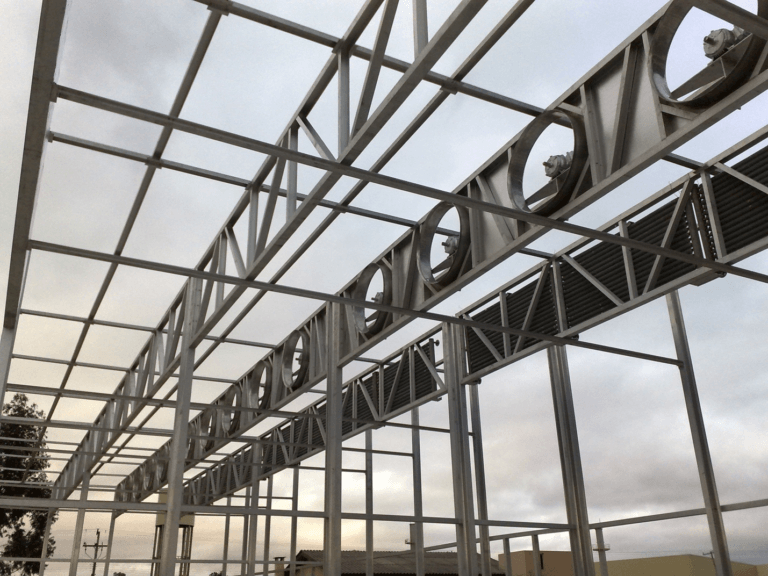

Frame Construction: Entire frame constructed from 6063 aluminum alloy, secured with stainless steel fasteners for structural integrity and corrosion resistance.

Frame Construction: Entire frame constructed from 6063 aluminum alloy, secured with stainless steel fasteners for structural integrity and corrosion resistance.