Conventional Wood Drying Kiln

Conventional Wood Drying Kiln

TECH Conventional Wood Drying Kiln is a versatile dryer. It can use steam, hot water, thermal oil, or electricity as the heating medium, operating at a drying temperature of 100℃ (212℉) or less. This makes it suitable for both softwood and hardwood, meeting various wood processing needs.

Our conventional kiln dryers, installed in 46 countries worldwide, are remarkable for their reliability and high efficiency. Our innovative technology precisely controls the drying process. This reduces lumber drying defects and ensures faster, more uniform drying, delivering high – quality results for our customers.

Hardwood and Softwood

30% Energy Savings

Built to Last for 20+ years

Kiln Specification

| Specification | Details |

| Model | ZQ Series |

| Capacity | 10?–?200?m3 |

Maximum Temperature Inside?the?Kiln | 100?℃? (212℉) |

Applicable?Lumber?Types | Softwood,? Hardwood |

| Loading?Method | Forklift |

| Kiln?Structure?Material | 3003+6063 Aluminum?Alloy |

| Heating Medium | Steam?/?Hot?Water?/? Thermal Oil/ Electricity |

| Site?Requirements | Indoor?/?Outdoor |

Key Features

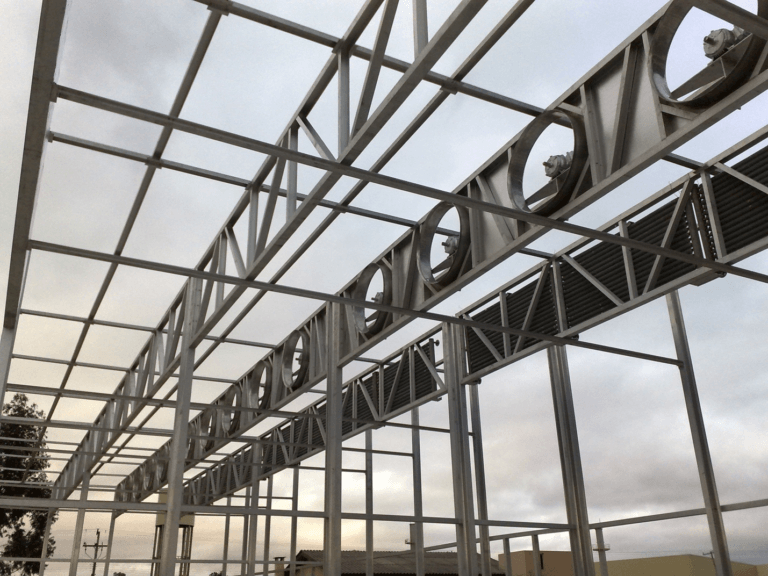

Robust Construction

Kiln chamber walls constructed with rust-proof 3003 aluminum; main structure built with 6063 aluminum. Heat exchanger pipes and all connecting parts feature 304 stainless steel, ensuring leak-free operation. Modular design enables easy maintenance. Ferrous-free structure guarantees 20+ years of corrosion resistance and stability.

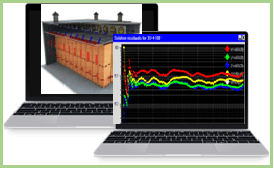

Optimal Moisture Control

The automatic control system enables precise regulation of temperature and humidity within ±0.5°C. It has remote-control and real-time data management functions, ensuring user – friendliness, as well as high efficiency and energy conservation.

Drying Technology

Over the 25+ years, TECH has scientifically engineered wood drying through rigorous species-specific research. Our multiphase drying protocols, validated via 10,000 in-lab tests, dynamically adjust to each species’ unique moisture diffusion and shrinkage patterns, cutting defects by 40%.

Integrated Design

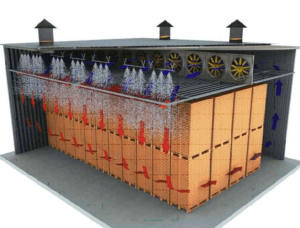

The kiln comprises six main systems: the heating system, the spraying system, the air circulation system, the venting system, the kiln door system, and the automatic control system.

Kiln Structure

System Design of Kilns

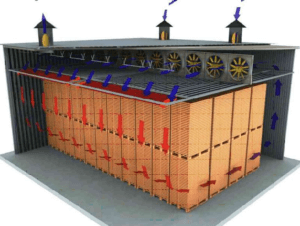

Air Circulation System

? Alluminum and Reversible Fans: All-aluminum, fully reversible fans feature symmetrical impeller blades, ensuring consistent airflow and pressure in both forward and reverse directions. This guarantees uniform moisture content in lumber across the entire airflow path.

? Integrated Baffling: Directs airflow through lumber stacks rather than around them, maximizing contact and wood drying efficiency.

? High Temperature & Humidity Resistance Motors: Internal motors feature corrosion-resistant casings designed for 100?°C / 100% RH kiln environments.;??Optional external motor systems tailored to specific airflow and environmental needs.

Heating System

? Robust Material Construction: Base pipes of heat exchanges, in-kiln pipelines, and all connecting parts are crafted from stainless steel, ensuring superior leak resistance and long-term durability.?

? High-Pressure/Temperature Capability: The heat exchanger is rated for safe continuous operation at 1.27 Mpa under steam heating conditions.

Smart Control System

? ??Precise Monitoring??

Equipped with multiple high-accuracy sensors, dry bulb and wet bulb thermometers to track in-kiln temperature, humidity, and moisture content.?

? ??Automatic Control?

The TECH PLC system automatically evaluates and executes based on sensor data and preset schedules, maintaining high?temperature/humidity precision for optimal drying uniformity.

? ??Remote Management??

The control system features a touch screen. Also, it enables remote control and real-time data monitoring via mobile/PC devices, significantly reducing manual inspections.

Integrated Design

The kiln comprises six main systems: the heating system, the spraying system, the air circulation system, the dehumidification system, the kiln door system, and the automatic control system.

- Heating System: Equipped with a high-temperature and high-pressure resistant heat exchanger. It can operate continuously under 1.27 Mpa when using steam heating.

- Spray System: Equipped with spray electric valves from a German brand. The spray pipes are made of ASTM 304 stainless steel, featuring high corrosion resistance and reliability.

- Air Circulation System: A symmetrical fan system ensures uniform air circulation in the duct. Fitted with an OEM aluminum – alloy fan and an insulated motor, it withstands 120°C and 100% humidity. This efficient air – flow keeps wood moisture content even for uniform drying.

- Venting System: Features Siemens electric damper actuators, compact and reliable. Aluminum gate – plate dampers offer low resistance, light weight and corrosion resistance

- Kiln Door System: It features excellent thermal insulation, is lightweight, corrosion – resistant and aging – resistant.

- ?