6 Repurchases: Kiln Dryers Power Gabon Africa's Timber Excellence

Rimbunan Hijau Group Made 6 Repurchases

Collaboration Since 2007

RH Group’s Gabon operations faced critical challenges in drying three key timber species under equatorial rainforest conditions (ambient humidity >85%):

- Mold Proliferation: Prolonged natural drying cycles increased fungal contamination risks, degrading Okoumé’s plywood-grade surface quality

- Okoumé (Aucoumea klaineana) Drying Defects: Rapid free water evaporation below fiber saturation point (FSP ≈30%) caused surface checking due to unmanaged moisture gradients drying wood drying process.

- Sipo (Entandrophragma utile) & Wenge (Millettia laurentii) Drying Defects: Internal stress accumulation during bound water removal (EMC <20%) led to warping and end splits.

Our Engineering Drying Solutions: Adaptive Kiln Systems & Process Control

1. Multi-Phase Thermal Management

- ?Preheating Stage: Saturated steam at 95°C/90% RH for 48hrs to equalize initial MC (45-60%) across species

- ?Free Water Removal (Okoumé): High-velocity airflow + 75°C dry-bulb temperature accelerated free water evaporation while maintaining wet-bulb depression <5°C to prevent case hardening.

- ?Bound Water Extraction (Sipo/Wenge): Reduced to 45-65°C with cyclic humidity spikes (15min @85% RH every 2hrs) to relieve hygroscopic stress.

- High Pressure Heat Exchanger: Sustains 1.27MPa steam pressure (35% higher than industry average) with <0.01% annual leakage rate.

- Siemens Linear Actuators: Activate aluminum dampers within 2s to purge moisture-laden air when MC exceeds FSP thresholds.

?2. Aerodynamic Optimization

- Symmetrical Al-alloy Fans:?Generate turbulent airflow to eliminate dead zones, achieving uniformity across timber stacks.

- ?Anisotropic Flow Design: Tangential airflow for Okoumé (radial/tangential shrinkage 1:2.3) vs radial patterns for Sipo to minimize warpage.

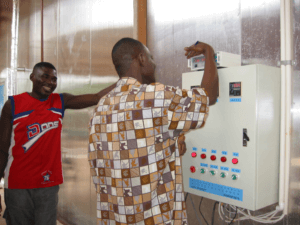

?3. Smart Control Ecosystem

- ?TECH PLC Control:0.5°C accuracy through PID loops integrating temperature test points and wood moisture content test points. The PLC control system allows the drying cycle to be divided into up to 11 stages, and each stage can be customized to meet the drying requirements of different types of wood.?

- Remote Management via Cloud Platform: The PLC control system is connected to the cloud platform, supporting remote monitoring operations on both mobile phones and PCs. It enables remote control of the equipment, real – time viewing of temperature and humidity change curves, data management, and receiving of alarm notifications, among other functions.

4. Structural Engineering Excellence

- Zero-Ferrous Architecture: 3003 Al-alloy rust-proof kiln chamber wall and 6063 Al-alloy kiln body structure optimized for tropical environments (RH>85%), these alloys passed 480hr salt spray tests (ISO 9227-CX grade), eliminating rust-induced structural degradation.

- ASTM 304 Stainless Steel Core Components: Demonstrated 15+ years service life in Gabon’s corrosive rainforest conditions, validated by RH Group’s 2007-2025 operational data.

Related Products

Conventional Wood Drying Kiln

TECH Conventional Wood Drying Kiln (ZQ Series) is a versatile dryer. It can use steam, hot water, thermal oil, or electricity as the heating medium, operating at a drying temperature of 100℃ (212℉) or less. This makes it suitable for both softwood and hardwood, meeting various wood processing needs.

Our ZQ series kiln dryers, installed in 46 countries worldwide, are remarkable for their reliability and high efficiency. Our innovative technology precisely controls the drying process. This reduces lumber drying defects and ensures faster, more uniform drying, delivering high – quality results for our customers.