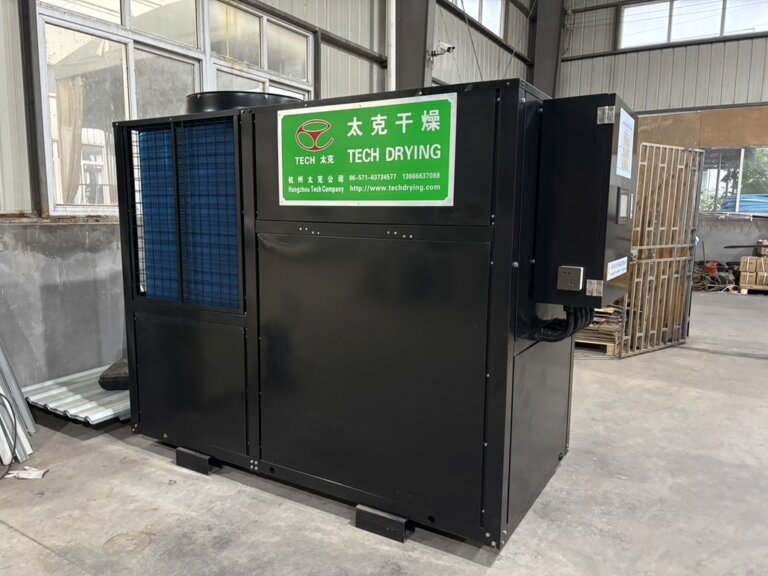

Dehumidification Kiln

Low-Temp Dehumidification Kiln

It operates at drying temp 27°C – 49°C and heat treating? 49°C – 70°C, ensuring excellent drying results for every load. It combines electricity and air-source heat (3 parts air energy + 1 part heat energy = 4 parts heating energy), saving up to 75% energy.

High-Value Wood, Delicate Wood, Secondary Drying or Wood Product Treatment

Excellent Wood Drying Quality

Saving 75% Energy

Dehumidification Kiln Specification

| Specification | Details |

| Model | KQN |

| Capacity | 20 – 40 m3 |

Maximum?Temperature inside?the?Kiln | 70 ℃ |

Applicable?Lumber?Types | High-Value Wood, Delicate Wood, Secondary Drying or Wood Product Treatment |

| Loading?Method | Forklift |

Kiln?Structure?Material | Polyurethane sandwich insulation panel |

| Heating?Medium | Air source heat pump |

| Site?Requirements | Indoor/Under rain shelter |

Key Features

Dual Heat Source

The kiln uses a combination of air energy and heat energy to provide energy efficient and environmentally friendly drying.

3 parts air energy + 1 part heat energy = 4 parts heating energy. It uses free air energy, saving up to 75% energy.

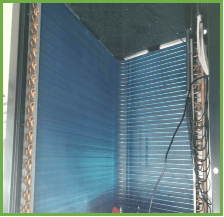

Excellent Insulation?

The 100mm thick polyurethane – sandwich kiln body shows unparalleled insulation and robust strength. Its thermal conductivity is extremely low, far better than ordinary insulation materials. This makes it an excellent heat – barrier, effectively blocking heat transfer. Plus, its remarkable strength ensures the kiln’s long – term stability and durability, minimizing heat loss by avoiding thermal bridge.

Reliable Components?

Using famous brand components like the US Copeland compressor, It adopts scroll technology, with an energy efficiency approximately 10% higher than that of traditional compressors. Featuring a dual – flexible design, it boasts high reliability.

Sanhua expansion valve, It precisely controls the flow direction of the refrigerant, enhancing the system’s efficiency and adaptability.

Working Principle of Dehumidification Kiln

The dehumidification kiln uses a heat pump as a key component of its dehumidification process.

A heat pump is a device that can both cool and heat the air, depending on the needs of the system. In the case of a dehumidification kiln, the heat pump serves the following purposes:

The heat pump works on the reverse Carnot cycle. In the evaporator, the refrigerant draws free heat from the outside air. Then, the compressor boosts the refrigerant’s pressure and temperature, turning it into a high – temp, high – pressure gas. This gas enters the condenser, releasing a substantial amount of heat to warm the kiln’s humid air for lumber drying. After heat transfer, the refrigerant passes through a throttling device to lower its pressure and return to the evaporator to absorb heat again. This cycle allows efficient heat extraction and use. The heating process is safe and eco – friendly, a leading energy – saving solution today.

Condensation of Moisture:

The heat pump pulls moist air from inside the kiln and cools it down using evaporator coils. As the air cools, the moisture in the air condenses into liquid water (similar to how dew forms on a cold surface).

This condensed water is then removed, ensuring that the air inside the kiln is drier.

Reheating of Air:

After the moisture is removed, the now-dry air is passed over the condenser coils of the heat pump, where it is gently reheated before being circulated back into the kiln.

This helps to maintain a consistent temperature ( drying temp 27°C – 49°C and heat treating? 49°C – 70°C), which is lower than traditional drying methods that often use much higher temperatures.

The gentle reheating is important because it avoids the risk of overheating or damaging the wood.

Energy Efficiency:

A heat pump is a highly efficient energy source because it transfers heat rather than generating it directly. In dehumidification kilns, the heat pump not only removes moisture from the air but also reuses the energy to heat the air back up. This makes the whole process more energy-efficient than traditional methods that rely on large amounts of electrical heat.