Kiln for Wood Packaging Materials (ISPM-15)

Kiln for Wood Packaging Materials

ISPM-15 and IPPC Standards

For Wood Packaging Materials

Applies to solid wood packaging materials like pallets, crates, and dunnage used in international trade, including materials like coniferous softwood and non-coniferous hardwood.

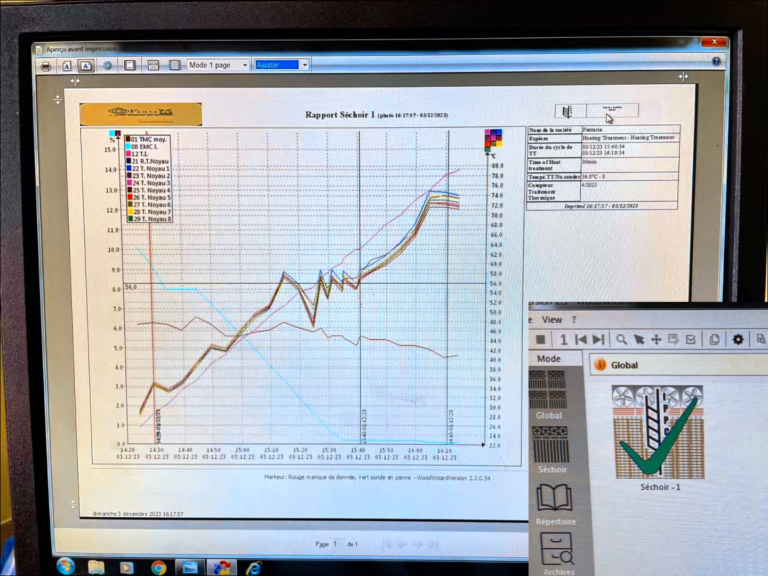

Wood Core Temperature Recording

Kiln Specification

| Specification | Details |

| Model | BZX |

| Capacity | 20 – 2000 m3 |

| Maximum Temperature inside the Kiln |

100 ℃ |

| Applicable Lumber Types | Wood Packaging Materials |

| Loading Method | Forklift |

| Kiln Structure Material | Aluminum Alloy |

| Heating Medium | Steam / Hot water / Thermal oil / Electricity |

| Site Requirements | Indoor / Outdoor |

Key Features

Intelligent Detection Function:

A wood core temperature detection module is added to conventional wood drying equipment. The system can automatically record (print) data like time, wood core temperature, kiln temperature and humidity (or wet – bulb temperature), and wood moisture content. It then transmits the collected data to a remote computer (commodity inspection department), enabling remote monitoring of the packaging box heat treatment process.

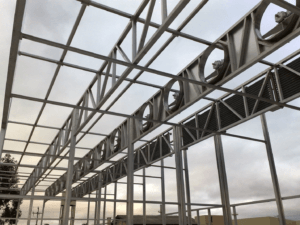

Robust Construction

Kiln Walls and body constructed with 3003 rust proof Al alloy and 6063 Al alloy. Heat exchanger pipes & all connections used ASTM 304 stainless steel.

Easy maintenance & assembly

Ferrous – free,

Corrosion – resistant

Long – term stability

Drying Technology

Over the past decades, TECH has been constantly refining the wood drying process. We’ve developed specific drying schedules for different wood species, which has remarkably enhanced the quality of dried wood.