Thermal Modification Kiln

-

-

Before Thermal Modification

-

After Thermal Modification

-

Thermal Modification Kiln

Hardwood, Softwood and Bamboo

180 - 250 °C (356 - 482 ℉) Heat Treatment

Thermal Break and Air Circulation Tech

Durable and Safe

Thermal Modification Kiln Specification

| Specification | Details |

| Model | HMY/HMD |

| Capacity | 20 – 40m3 (Customizable for other sizes) |

| Maximum?Temperature? inside?the?Kiln | 250 ℃ (482℉) |

| Applicable?Lumber?Types | Softwood, Hardwood and Bamboo |

| Loading?Method? | Rail and Trolley |

| Kiln?Structure?Material | 304 Stainless Steel Inner Wall |

| Heating Medium | Electricity / Thermal Oil |

| Site?Requirements | Indoor / Under Shelters |

Key Features

Energy Saving and Safe Operation

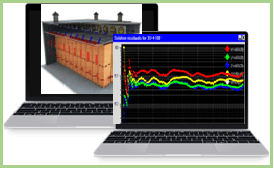

Smart Control

The upgraded control system enables precise regulation of temperature and humidity. It enables remote control and real time data management , ensuring user friendly, along with high efficiency and energy conservation.

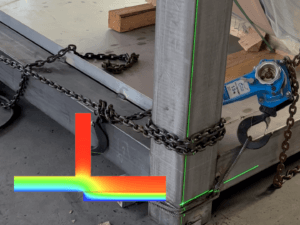

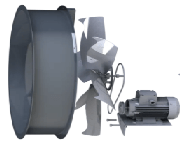

Air Circulation Technology

The unique design of the fan shaft structure and bearing lubrication enables the fans to be positioned anywhere within the kiln as required. This allows for precise regulation of the air dynamic circulation, ensuring a uniform heat flow distribution. Consequently, the drying uniformity and efficiency of the lumber are enhanced.

Drying Technology

Over the past decades, TECH has been constantly refining the wood drying process. We’ve developed specific drying schedules for different wood species, which has remarkably enhanced the quality of dried wood.

What is Thermal Modification or Heat Treatment of Wood?

Definition: Wood carbonization (thermal modification) refers to the heat treatment of wood at high temperatures ranging from 180 to 250 °C.

Principle:? High – temperature degrades hemicellulose in wood. The generated organic acids speed up the degradation of hemicellulose and cellulose’s amorphous regions, reducing hygroscopic hydroxyl groups and increasing the crystalline region, thus enhancing dimensional stability. Degradation produces organic acids and phenolic compounds that inhibit decay – causing fungi, strengthening decay resistance. With fewer hygroscopic hydroxyl groups, the wood’s outdoor moisture content variation lessens. High – temperature treatment also creates photo – aging – resistant compounds, improving weather resistance. Difference from Surface Carbonization: It is not surface carbonization for decoration only, but uniform carbonization across the whole wood cross – section.

Product and Its Advantages: The product is thermally – modified wood (carbonized wood), boasting excellent dimensional stability, decay resistance, and weather resistance.?

Application: It is especially suitable for geothermal floors and outdoor use.